Positive displacement pumps are pivotal in fluid handling applications across various industries due to their distinct operational capabilities and efficiency. These pumps are valued for delivering a consistent flow, irrespective of viscosity changes or differential pressures.

Operational Dynamics

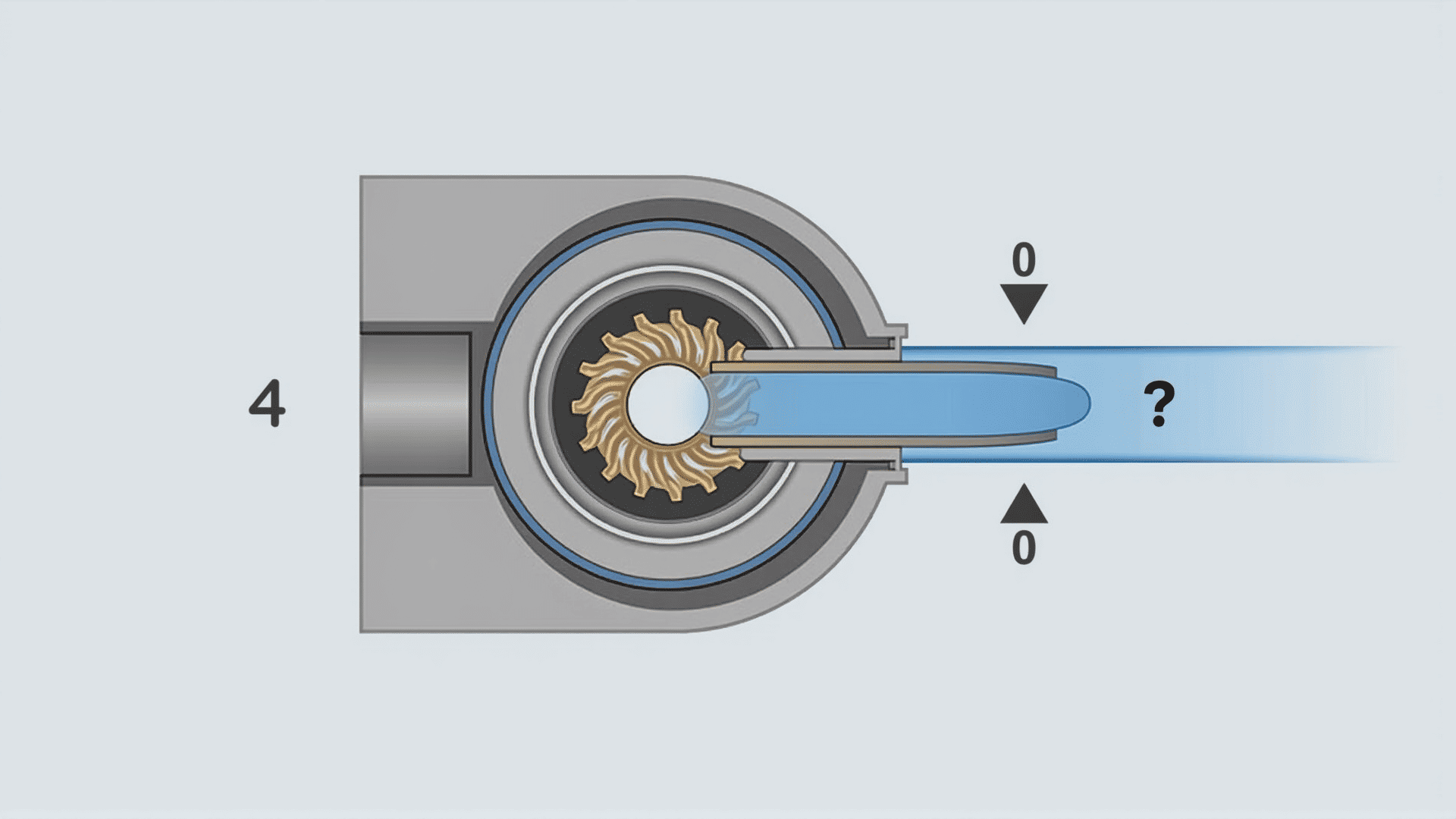

Positive displacement pumps operate by trapping a fixed amount of fluid in a compartment and then displacing that trapped volume into a discharge pipe. This mechanism involves either the rotary or reciprocating motion, based on the pump’s design, to transfer fluids. Two primary types of positive displacement pumps exist: rotary and reciprocating. Rotary pumps use gears, lobes, screws, or vanes rotating within a chamber, whereas reciprocating pumps employ pistons or diaphragms moving back and forth.

Throughout their operation, these pumps maintain a uniform flow, which is a significant advantage over dynamic pumps when dealing with high-viscosity fluids or substantial system pressures. This steady flow ensures precision in liquid handling, making them an ideal choice for metering or dosing applications.

Mechanical Efficiency

An impressive feature of positive displacement pumps is their mechanical efficiency, attributed to their ability to handle a wide range of viscosities and pressures with minimal energy wastage. These pumps operate with high efficiency even at varying pressures, maintaining a steady flow rate, unlike centrifugal pumps, which can suffer from efficiency drops under similar conditions.

Their design minimizes internal slippage, a common problem in handling thicker fluids, thus enhancing energy efficiency. Furthermore, positive displacement pumps are designed to create a vacuum at the inlet, enabling high suction lifts and efficient air removal from the lines.

Applications and Advantages

These pumps find applications in chemical processing, pharmaceuticals, oil and gas, and even food processing due to their reliability in moving fluids without changing their properties. The gentle handling of sensitive fluids ensures that product integrity is maintained, which is essential in industries like food and pharmaceuticals.

Moreover, positive displacement pumps offer versatility with their ability to operate efficiently across a variety of temperatures and pressures. They are robust, provide precise flow control, and have the capability to handle fluids laden with solids or air, making them invaluable where accuracy, reliability, and consistency are crucial.

In conclusion, positive displacement pumps are integral to systems requiring a steady and reliable fluid transfer. Their inherent efficiency in handling various fluid conditions, coupled with their robust design, ensures their continued use across diverse applications, cementing their role as a core component in efficient fluid management systems.