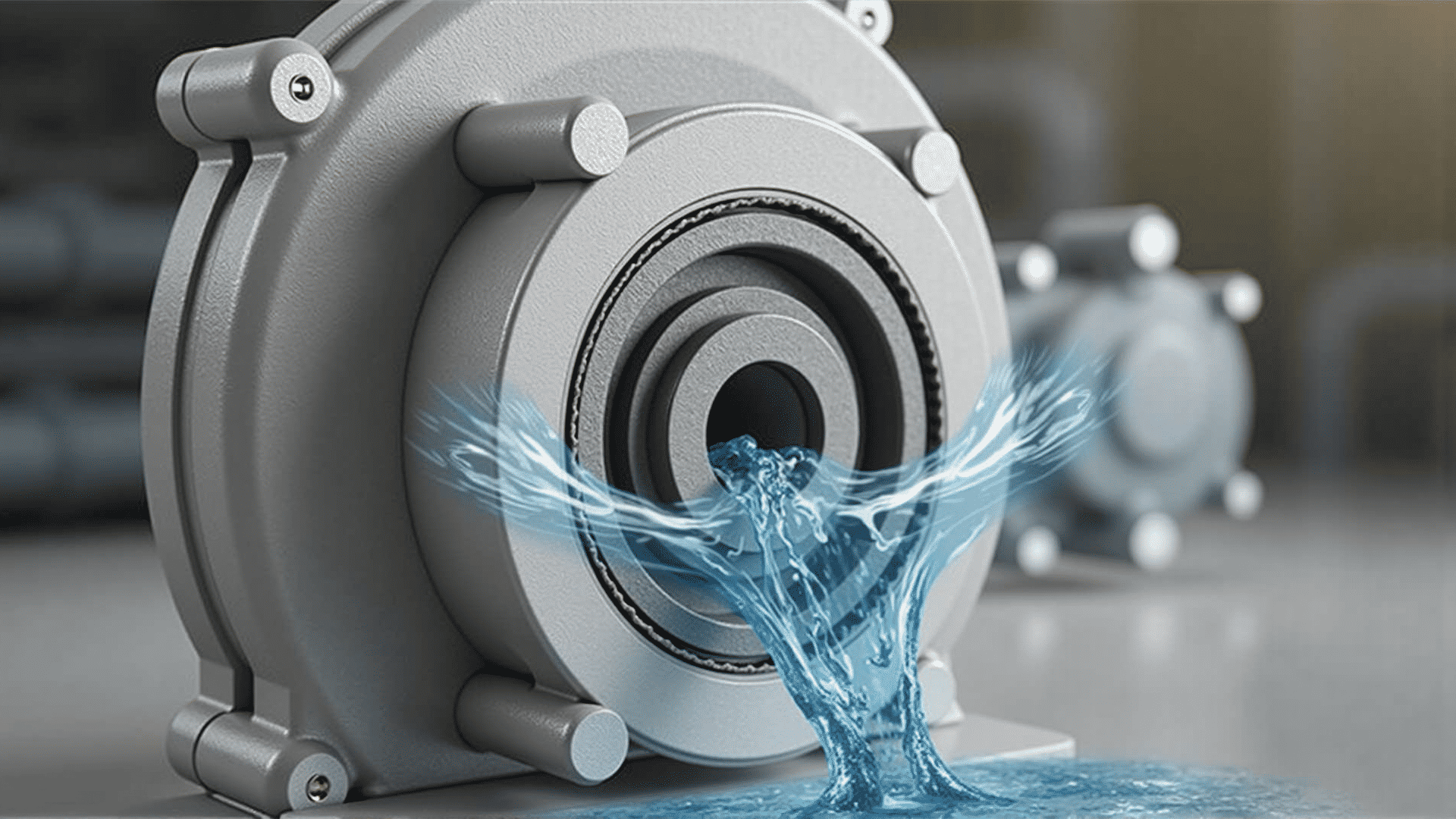

Diaphragm pumps are a remarkable solution in the world of fluid transfer, known for their reliability and adaptability across various sectors. These pumps employ a simple yet effective mechanism that enables them to move a range of liquids with precision and consistency. Characterized by their robust construction and versatility, diaphragm pumps are often seen as an indispensable component in many industrial applications.

The principle behind diaphragm pumps is relatively straightforward. They utilize a flexible diaphragm, usually made from rubber or a similar synthetic material, which is actuated back and forth to create a vacuum. This vacuum draws in the fluid, and then as the diaphragm moves in the opposite direction, it pushes the fluid out, thus facilitating the pumping action. One of the standout features of diaphragm pumps is their ability to handle both viscous and particulate-laden fluids without risking damage to the pump. This makes them particularly suited for operations that involve abrasive or corrosive substances.

In the realm of chemical processing, diaphragm pumps shine due to their durability and efficiency in managing aggressive chemicals. Their ability to maintain performance without leakage is critical when dealing with potentially hazardous materials. In addition, they are particularly useful in water and wastewater management, offering an effective method of transferring sludge and slurries.

Beyond industrial uses, diaphragm pumps find significant applications in the food and beverage industry. Their capacity to handle viscous liquids while maintaining the integrity of the product is crucial, ensuring that no contamination occurs during the process. Additionally, the pharmaceutical industry benefits from these pumps, wherein precise dosage and contamination-free transfer are paramount.

Another advantage of diaphragm pumps is their capacity to operate without electricity, making them ideal for operations where power supply may be inconsistent. This flexibility allows them to be utilized in remote locations or portable applications with ease.

Furthermore, diaphragm pumps are known for their self-priming nature and ability to run dry without damage, which expands their range of applications. They are frequently used in environments where other pumps might falter, demonstrating exceptional endurance and adaptability.

In conclusion, diaphragm pumps offer a reliable and versatile solution for a wide array of fluid transfer applications. Their design accommodates a broad spectrum of liquids, from delicate substances to harsh chemicals, ensuring efficiency and safety. As industries continue to evolve, the role of diaphragm pumps in ensuring seamless and precise fluid management is likely to expand even further. Their robust performance and adaptability make them an invaluable tool in various sectors, reflecting their enduring appeal in fluid dynamics.